The steel-bolted and gasket-sealed water tank plays a crucial role in the fire protection system for the Jenolan Caves Reserve. Providing 241,000 litres of water in the likelihood that there is a fire on site. However, the situation evident was that the roof support system had corroded, and wall panels and internal componentry had been overcome by corrosion also, significantly decreasing the structural integrity of the tank, which poses as a significant risk of catastrophic failure. Another unique challenge was that access to the fire tank was limited as it was located on the face of a steep hill with no vehicle access.

To address these concerns and ensure the prolonged functionality of the fire water tank asset, STS CIVIL executed a comprehensive solution. Overcoming the accessibility hurdle, helicopters were utilised to transport tools, parts, and components to and from the site, facilitating the removal of old components and debris. Subsequently, the tank underwent thorough cleaning to remove all debris and sludge before commencing the support system upgrade.

The support system transitioned from submerged pole supports to a raised truss support system, enhancing structural integrity. Wall panels were replaced, and all nut and bolt components were upgraded to mitigate corrosion risks. A custom-fabricated stainless-steel SWAH was installed, alongside a new roof access hatch and interior and exterior ladder extensions, ensuring safe and seamless future maintenance and servicing.

After preparing the steel base we commenced the installation of protective geotextile fabric and a new PVC food-grade liner manufactured by C. E. Bartlett Tank Liners in Ballarat, Victoria, Australia. Additionally, new overflow piping, inlet, and outlet fittings were installed to guarantee seamless functionality.

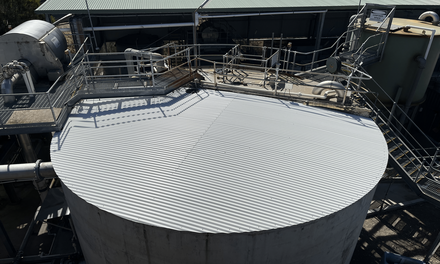

Through the strategic replacement of corroded components and structural upgrades, the lifespan and reliability of the fire water tank asset have been significantly extended, safeguarding against potential risks.At the power station, three lined panel tanks play a critical role in supplying demineralised water to cool down the four gas turbine generators used in the production of backup electricity during periods of high demand or in the event of major failure of the transmission system. However, behind the liner, internal corrosion to the walls, roof and truss system had compromised the structural integrity of these tanks, posing as a significant risk of catastrophic failure.

To address this challenge and extend the lifespan of these demineralised water tank assets, STS CIVIL provided a comprehensive solution. This involved cleaning and removing the existing liner, internal fittings, roof, flashing, truss support system, and SWAH. Following this, is the installation of the new truss support system, along with protective measures such as the installation of condensation strips and roof sealant. The condensation strips and roof sealant prevent the condensation run off path from going behind the liner, preventing further internal corrosion to wall panels. Additionally, we treated existing corrosion on the tank’s internal walls with preparation of the surface and then the application of specialist surface treatment paint to inhibit further internal corrosion to the wall panels. After corrosion prevention was the installation of protective geotextile fabric and new Industratex® liner manufactured by C. E. Bartlett Tank Liners in Ballarat, Victoria, Australia. Throughout this process, we refurbished and reinstalled original fittings, ensuring seamless functionality. Once the new fabricated SWAH was installed and other internal works were completed, the roof was installed along with a new ventilator system and reinstallation of existing monitoring equipment.

By addressing the main cause of corrosion and implementing robust protective measures, we have significantly prolonged the lifespan and reliability of these demineralised water tank assets. This safeguards uninterrupted operation during periods of high demand or in the event of major system failure.

A treated water tank is in need of substantial rejuvenation to uphold its integral role in the water treatment process. The existing liner has developed leaks, while the tank's trusses and support pole systems have succumbed to corrosion, necessitating replacement along with the tank fittings to mitigate the risk of failure and prolong the tank's active lifespan.

In response to this challenge and to ensure the prolonged functionality of the treated water tank, STS CIVIL has devised a comprehensive solution. The process commences with the draining and cleaning of the tank, followed by the removal of the existing liner. Additionally, wall and roof panels above the fittings are dismantled to facilitate crane access for their replacement.

Subsequently, the corroded wall panels and bolts are replaced, and significant support upgrades are implemented. This involves substituting the support posts with new, durable stainless-steel alternatives and installing a new roof truss system. Protective geotextile fabric is then installed on the floor and walls, followed by the placement of a new Industratex® liner manufactured locally by C. E. Bartlett Tank Liners in Ballarat, Victoria, Australia. Throughout this process, new custom-fabricated fittings are seamlessly integrated to ensure optimal functionality.

To conclude the tank rejuvenation, thorough disinfection is performed, followed by the commencement of tank commissioning. Additionally, exterior gate access is installed around the tank to enhance security and access control to the asset.

Through the strategic application of protective measures and the diligent addressing of corrosion and leakage issues, we have significantly extended the lifespan and reliability of the treated water tank. This ensures the uninterrupted operation of the water treatment process, bolstering its efficiency and effectiveness.The two wastewater tanks serve as vital components within the wastewater treatment system, facilitating efficient processing. However, prolonged exposure to weathering has compromised the structural integrity of their existing liner material roofs.

In response, our solution aimed to enhance the longevity and reliability of these wastewater tank assets. We removed the deteriorated material roofs and cable support systems. Subsequently, we installed our custom-designed truss support systems, incorporated new access ladder brackets and ladder fitment, and installed the new Australian-made steel roofs from BlueScope Steel.

Through this comprehensive upgrade and rejuvenation, we have significantly prolonged the operational lifespan and reliability of these wastewater tank assets, safeguarding the uninterrupted operation of the facility.